Mold Precision & Vanderhorst are teaming up to host a food drive for a local food bank

It’s been a tough few months and some people have lost their entire livelihood. Some people are trying to decide if they will buy food or pay rent. We want to help out. Here’s a list of the things they need most.

Manufacturing Sustainable Resources for Covid-19 Testing

Mold Precision is proud to be able to be a part of the solution during the Covid-19 Pandemic by manufacturing sustainable resources such as these sample collection funnels for Covid-19 testing to help prevent the spread of the virus.

Mold Precision Engineering recognized in Quality Leadership 100 Quality Magazine

Mold Precision Engineering recognized in Quality Leadership 100 Quality Magazine, February 2020.

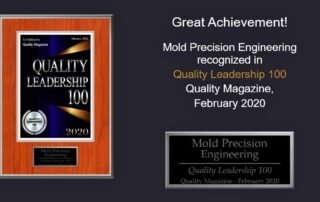

Plastic Injection Molding Process Overview, Step by Step

Plastic Injection Molding Process Overview, Step by Step THE PLASTIC INJECTION MOLDING PROCESS The stages of the plastic injection molding process are considered when analyzing parts design, tool creation and efficient production of molded plastic parts & products. This article glosses over some details and covers the basics.

motionMounts.com, Recognized as NASA Top 10 Innovation

In March of 2019, motionMounts was recognized as a NASA Top 10 Innovation. Mold Precision Engineering takes pride in seeing our client successes The Project : motionMounts Established in 2011, a Utility Patent was issued to inventor, Jeffry Voorhees for the first mounting solution to support the use of an iPad®.

Mold Precision is proud of Flex Knit Needles’ Innovations Finalist Award at the Creativation Show

Flex Knit Needles was an innovations finalist at the - awarded by the Association of Creative Industry at the Creativation Show. Marlene Tabibian, client of Mold Precision and inventor of Flex Knit: a patented, flexible and ergonomic straight knitting needle designed to improve comfort during knitting by enabling bending with resiliency at the wrist level. Patented Ergonomic Bendable Straight Knitting Needles!

Mold Precision Engineering Recognized in Top Quality Leadership Rankings

It's nice to know that our dedication to quality & precision is appreciated. Mold Precision, Engineering is recognized in the Quality Leadership list for 2019. Quality Magazine ranks companies on the following factors: continuous improvement and internal quality programs; contribution of quality to profitability and shareholder value; average number of hours that employees receive quality training; scrap and rework as a percentage of sales; warranty costs as a percentage of sales; and registration to various standards such as ISO 9001.

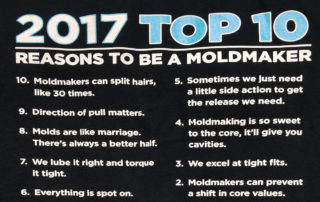

Mold Making Technology : Mold Precision’s Peter, conceives 2 of the Top Reasons to be a Moldmaker

Mold Precision's Peter Minaskanian, conceives 2 of the Top 10 Reasons to be a Moldmaker. #1 "Moldmakers can split hairs, like 30 times." #2 "Moldmaking is so sweet to the core, it'll give you cavities." Annually, at Amerimold, the Mold Making Technology Top 10 Reasons to Be a Moldmaker are revealed and printed on the back of the event's tshirt.

Customer project tour & testimonial : Magic Brush Saver

The Magic Brush Saver is a clever invention that you can attach to any brush and allows you to properly rest the brush on the side of a bucket to keep it out of the paint. The Magic Brush Saver was intended for professional and DIY use -- and helps save you time & money on new brushes. Ray Hepinstall, was inspired to invent the Magic Brush Saver while working as a professional painter over 30 years. He invented the Magic Brush Saver to keep the brush where it belongs - near the paint. Being of creative character, Ray is has been a musician since he was 12 years old - click here to check out his music.

How Can My Project Benefit From A Multi-Cavity Injection Mold?

A multi-cavity mold is a a custom plastic injection mold with multiple cavities of the same part that is typically used to reduce piece-part pricing for higher volume parts. If you want more than tens of thousands of parts per month, then a Multi-Cavity Mold is for you. Mold Precision recommends more than a single cavity mold when the capacity is going to be greater than 40,000 pieces a month.

Custom Plastic Injection Molding and your Project

Custom plastic injection molds are used in injection molding processes using an injection molding machine such as the Engel 40 Ton Tiebarless Injection Molder (shown below). These are generally used to produce plastic parts using a core and a cavity, runners & gates. Plastic Injection Molding is a manufacturing process for making plastic parts in large volume. It is generally used in mass-production processes where the same part is being created thousands or millions of times in in a cycle.

MPE and MIT

MIT is probably the country's premier University for Engineering. Their reputation for cultivating great minds with world changing ideas is unparalleled. You are probably wondering how I have the right to put Mold. Precision Engineering's name next to the name of such a great learning institution. I'm glad you asked because now I can show you my summer vacation photos and tell you "what I did on my summer vacation".

Multi-Cavity, Single Cavity, Mold Insert, MUD Insert, Mold Base

I often get asked "Why is there such a wide spread in mold costs?" If the age old proverb says "You get what you pay for", then the next question is "What am I paying for?" In as few words as possible, I am going to try to explain this, but if I answered this question without writing about molded piece costs, I wouldn't be doing it justice. You probably already know, if you are buying a mold, it's because you want molded parts at the least total cost at your desired quality that meets your scheduling requirements. Therefore, I think it would be best if we talked about this in those terms.

Keywords/Services

Keywords / Services: Injection Molding, Custom Injection Molding, Plastic Injection Molding, Plastic Injection Molds, Custom Plastic Parts, Custom Plastic Assemblies, Plastic Manufacturer, Plastic Part, Plastic Parts, ABS Plastic Molding, ABS Parts, Polycarbonate Plastic Molding